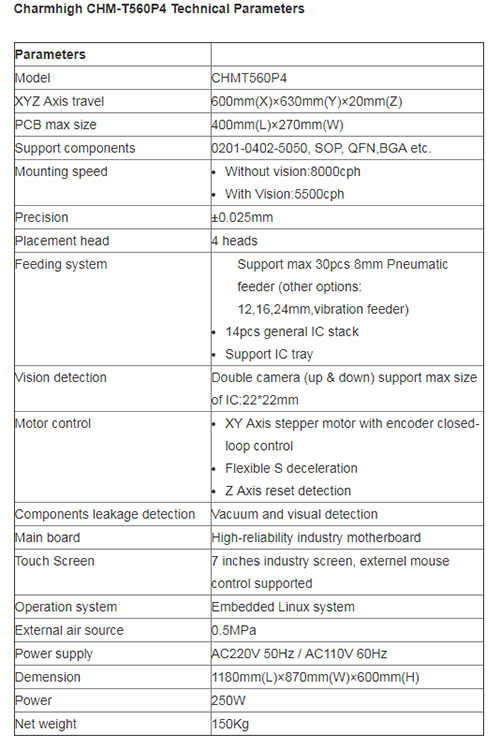

CHMT560P4 4 nozzles pick and place machine

Standard Accessories for CHMT560P4:

HS Code 8479.89.92.00 Automated electronic component placement machines of a kind used solely or principally for the manufacture of printed circuit assemblies.

1) Pick and Place MachineCHMT560P4: 1

2) Juki nozzle: Totally 4pcs (503, 504, 505, 506 size)

3) 8G USB flash 1

4) Power Cord: 1

5) Grease: 1

6) Hex wrench: 6

7) Tweezers: 1

8) Brush: 1

9) English user manual: 1

Pneumatic Feeder is Not included, welcome your inquiry, 60 feeders we can offer you the best price. CHMT560P4 compared with CHMT510P4 which owns more rich applications, can be used Not only in LED strips but also in prototyping or small batch PCB surface mount production.

CHMT560P4 User Manual

High Precision Motion Control System, industrial automation equipment, electronic Components SMT technology

XYZ Axis Stroke 600mm*630mm*20mm

PCB Board:10*10-400*270mm

Component Support 0402, 0603-5050, SOP, QFN, BGA

Material Support: YAMAHA CL Pneumatic Feeder

Power: AC 220V 50Hz/AC110V 60Hz

Dimension: L1180mm*W870mm*H600mm

Need External PC: With Quality Industrial PC

Power: 250W

Air Supply 0.5Mpa

Net Weight: 130kg

Nozzle: 4pcs

Mount Speed: Do not use the visual:8000cph, use visual:5500cph(cph is chip per hour)

SMT precision: 0.015mm

Material Feeding System: 60pcs feeders CL82, CL84, CL12, CL16, CL24, pre-IC tray: 14pcs general IC stack, support custom IC tray, vibration feeder are available and can be purchased separately.

Controlling system: XY axis with motor for driving, Z-axis with reset detection All motors with S flexibility lower or faster speed

Compatible operating Embedded Linux system

Vacuum Detection: Vacuum detection, visual detection

Visual system UP Camara automatic adjust(max22mm*22mm), Down Camara PCB automatic MARK adjust

CHMT560P4 is a multifunction pick and place machine that can load traditional pneumatic feeders, the precision and speed are surely better than CHMT36VA or CHMT48VB benchtop type Not only because of the working principle but also for small SMT components 0201 or 0402. The pick and place machine CHMT560P4 together with T-961 reflow oven and the 3040 classic stencil printer is the cost performance SMT production line for batch production IoT or LED, etc.

Chat Online

Chat Online