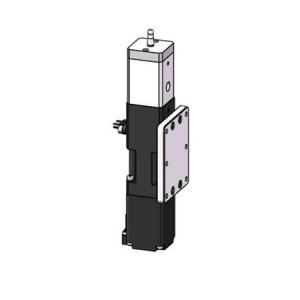

Ceramic Injection and Metering Pump

57SAS series Ceramic Piston Pumps are designed for metering or dispensing lower-viscosity chemical liquid and pure biochemical liquid. Without a dynamic seal, this type of pump is maintenance-free by adapting a precise fit ceramic plunger and sleeve. A reliable rotary drive system provides very high repeatable accuracy for each turn.

Features

Corrosion resistance to acid or alkali fluid or chemical reaction. Compatible with most fluids.

The elastic sealing approach for fluid inlet and outlet provides more reliable sealing.

Maintenance-free design. Almost zero wearing parts. Helps customers maximize machine uptime. Minimize machine downtime and maintenance costs.

Dispensing and loop operation mode. Forward and reverse direction motion mode.

Rich control interface selections. Medium / high torque motor selection.

Wearing resistant. No moving sealing O-ring (tens of millions of operations without wearing)

Ceramic pump modules can be customized per the customer's requirements.

Typical Applications:

Lithium battery electrolyte injection

Fluid drug dispensing or filling

The reagent dispensing or filling

Spraying or coating

Silicone oil atomizing and spraying

Contact lens dispensing

Flavor, essence, and liquid vitamin additions

Application:

A lithium battery injection pump is a kind of plunger-type precision metering pump for metering transportation or quantitative perfusion of chemical liquid and high-purity liquid. Ceramic plunger and plunger set with precision, no dynamic seals, and durable wear. The pump uses the stepper motor rotation to drive the ceramic plunger for the rotation and reciprocating motion, the plunger rotation in the opening and closing of the inlet and outlet channels at the same time, the precise synchronization of the plunger for reciprocating movement caused by the cylinder liner volume changes, To reach the suction, drainage of liquid medium, without the need for quantitative control of the liquid through the inlet into the sleeve cavity, and then the liquid out of the mouth through the mouth of the cavity, and then through the pipeline into the user equipment or products.

Lithium battery injection pump in front of the pump with a special sealing device can play an isolated air, and dust role, greatly improving the crystallization, card pump and other issues. The pump can be adjusted by adjusting the pump head angle to determine the plunger stroke to calibrate the amount of fluid per lap, the pump does not produce trace impurities or contaminated liquid. Just release the fastening bolts, will be able to remove the pump head plunger components for cleaning and maintenance, especially for chemical liquids, pharmaceutical biochemical, and other high-purity liquids.

Lithium battery injection pump has a very high measurement accuracy and repeats consistency; accuracy is better than ± 0.5%.

All 304 stainless steel pump body structures and all parts of the pump have better corrosion resistance.

Color touch screen controller, built-in high-performance drive and control program can be set for a variety of operating parameters and operating modes: metering delivery, continuous multi-circle injection, suction, backflow and so on.