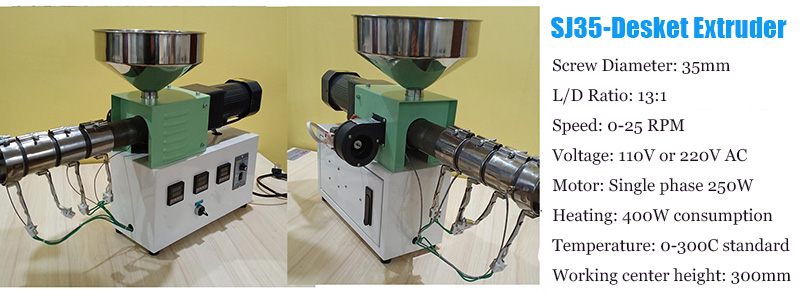

Desktop SJ35 Extruder

SJ35-Desket is part number for the Desktop Extruder

G-Pelletizer filament cutting into pellet machine

SJ35-GL is a granulating production line that includes the SJ35-Desket Extruder, water-cooling tank, and the G-Pelletizer.

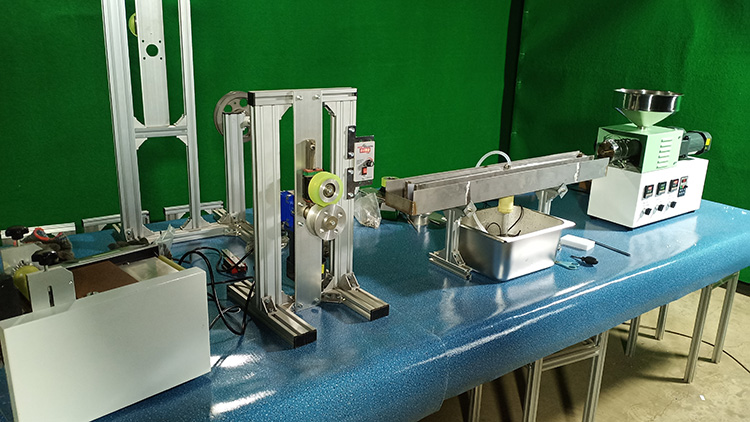

SJ35Line is a filament production line that includes an SJ35-Desket Extruder, water cooling tank, Tractor (it's different from GL-Tractor), Spooling Unit (Arrangement and Metering). The filament diameter measuring unit (Laser Gauge?) is Not included.

SJ35 extruder for 3d printing filament or granulating line in laboratory or institute.

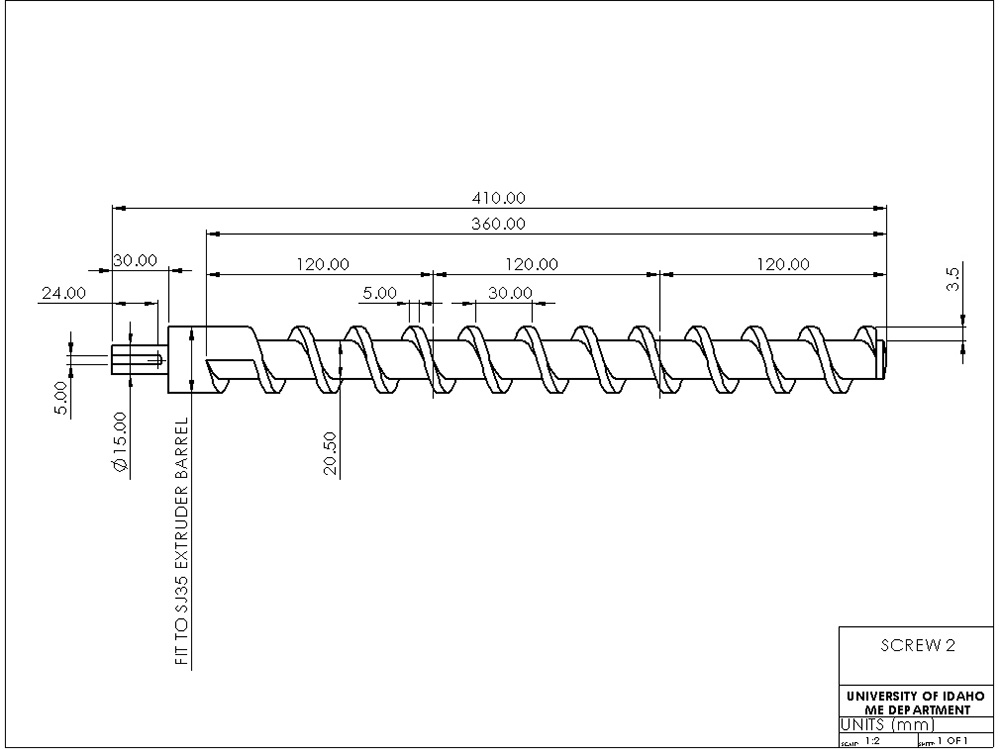

Desktop type 35mm diameter extrusion screw and 12:1 length diameter ratio which is 400mm effective working length.

Desktop Filament Production Line

Filament production line (in the video, the laser gauge are separately available)

Desktop granulating or pelletizing line

Water cooling tank

Tractor

Pelletizer or granulator

SJ35-Desket is only the SJ35 extruder on the very left.

G-Pelletizer is a machine used to cut the filament into pellets, tractor function built-in (there is No need for an extra filament tractor).

SJ35-GL is the whole above 3 parts and the water cooling tank you can find in the picture.

Desktop Tubing Extrusion Product Line

With an add-on Tubing DIE, the SJ35 Desktop Extruder can be used for tubing extrusion size below 10mm.

More readings on the Desktop SJ35 Extruder

With the G-Pelletizer, you do Not need a separate Tractor for the filament traction.

Parameters of desktop pelletizer:

Voltage: 220v (110V optional)

Power: 370w

Speed: 0-100 RPM adjustable

Control method: frequency convertor speed regulation /VFD

Output 0.1-5kg/h

Length, width, and height: 500*500*450mm

SJ35-Desket-H high-temperature extruder up to 500C, Servo Motor

PET Recycling Practical Notice:

The SJ35Line filament production line can be used for PET Recycling. About the tolerance, it's practical to adjust the speed of the extruder and the tractor, because the extruder and the tractor do not have a synchronously controlling system. Our practical tolerance could be +-0.05mm.

1. Make sure the temperature of the screw and barrel zone reaching the melt for the PET and then to start the Extruder. Temperature does Not reach may cause the extruder, especially the motor getting hot, also the screw is easily worn out.

2. You need a hot water supply in the cooling tank, to keep it 60-70 centi-degree would be good, we use an induction cooker to keep warm. :-)

3. Keep the extruder and the water tank as close as possible, then the filament can be cooled down ASAP.

4. The temperature of the DIE (Nozzle) as lower as the extrusion can be extruded out.

5. Make sure the filament between the extruder and the tractor tightly and submarine the hot water in the cooling tank.

SJ35-S410UoI 35mm diameter plastic screw designed by University of Idaho ME Department for the SJ35 Extruder