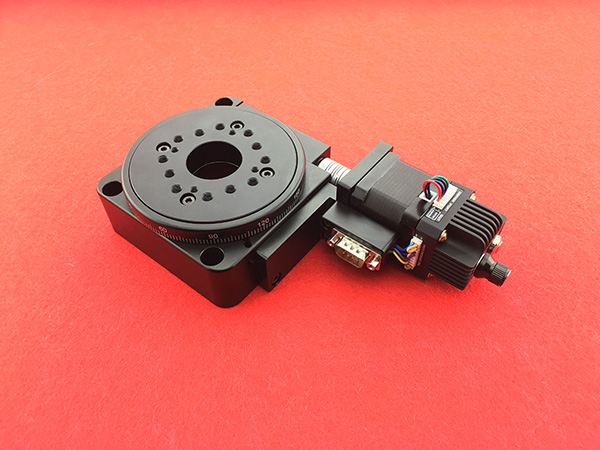

Integrated Stepper Motorized Rotary Table

Rotary Table

Instruction on how to operate with RobotDigg integrated stepper motorized rotary table?

This is the power interface, the input voltage is 24VDC , and the current is 3A. Be careful that the positive and negative poles can’t be reversed when wiring, otherwise the driver will be burnt.

This Yellow one is direction switch, and this green one is enable switch, press it and motor go offline.

This blue ones is a high speed and low speed switch, it is for the potentiometer, if it is 1-50K speed adjustment after pressing, the stage will be 0.01°- 0.5 °rotation adjustment, this is a specific function for this rotary table.

Stepper motor is 1.8 degree NEMA17 40mm size, and this one is a coupling for connecting motor with rotary plate.

And this is our All in one stepper motor driver controller, potentiometer is for speed control in running condition. And this is a physical button what we can do mean setting or opreation mode control.

This is rotary plate with scale, plate can rotate, but shaft can’t be rotated , it needs to be rotated by motor or manually.

It’s a DB-9 connector, this connector can’t be plugged when powered, otherwise may cause damage of the driver.

Now, let’s power it up, After power-on, our drive is working in "08" mode, and the 08 mode is custom make for the rotating plate. Let's do it now.

When all switches are reset, turn the potentiometer from 1-51, which means from 0.01-0.5°

Let’s take a look at this coupling, the speed is the lowest when it’s in “1”. Then let’s switch it to high speed, now is low speed condition, press it. Now the speed it 1K - 50K, the maximum rotation speed of 51K, and the current rotation speed is 51K. We can adjust the rotation speed.

This is the direction switch. When we press it, the motor runs in the opposite direction.

Now let’s switch back to low speed, press “enable ”, the motor is online, we can rotate motor by our hand.

Switch off “enable”

Over...