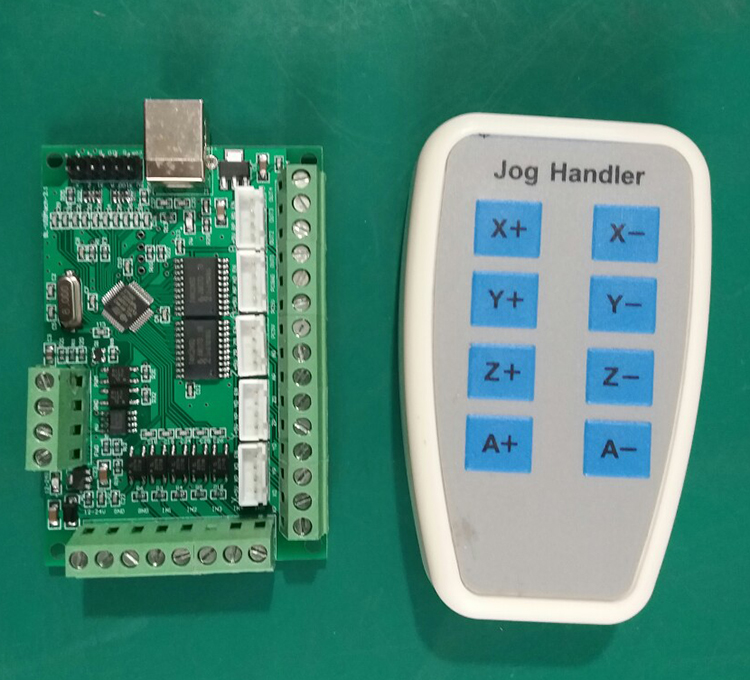

USB CNC Controller V.S Mach 3 USB Controller

USB CNC Controller

PC hardware requirements: CPU-1.6G above, RAM 1G above

PC system requirements: Windows XP, Vista or Windows 7 (32 bit or 64bit)

Support standard G-codes profile: like*.nc、*.tap profile; SW, UG, PW such software support

Support 4-axis, 25 kHz maximum step frequency, Max. simultaneously output frequency 100K

Support CAD software DXF profile: PLT/HPGL

Support line cutting

Support 4-axis limit function

Support tool setting function

Support back to original function

Support tool changing function

Support main-axis speed control, switch control, water cooling, spraying control.

Support all function keyboard shortcuts

Support continuation on break point function

Support common CNC function: mirror, translation, circuilation, etc.

Features:

Compatible ESD, EMI, EMC

Adapts optical coupling isolation design

Use TVS for interface safety protection

Core chip all metal shield design

Special USB cable, high anti-interference ability then normal blue USB2.0 cable

The first with hardware self-test function USB CNC controller

Mach3 USB CNC Controller

1. Support for 4-axis linkage, you can connect four stepper motor drives or servo drives;

2. Maximum step-pulse frequency is 100KHz,which is suitable for the servo or stepping motor;

3. 4 general-purpose opto-couplers isolation input : can connect the limit switch, emergency stop witch, auto tool zero, home switch etc.

4. Support for connecting electronic handwheel;

5. Have 0-10V signal output , you can use mach3 software to control the spindle motor speed.

6. 4 general-purpose isolated relay drive output interface, can drive four relays for controlling the spindle starts, forward rotating and reverse rotating, pumps or other device;

7. 1 status LED, indicate connection status on the board.