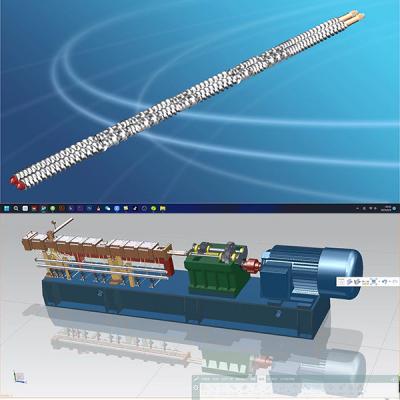

Block type twin screw and barrel

Elevate your extrusion process with our high-performance Modular Block-Type Parallel Twin Screw and Barrel. Designed for maximum versatility, this system features a "building block" architecture that allows for precise customization of the screw profile and barrel layout. Whether you are compounding polymers, facilitating reactive extrusions, or processing complex materials in the food and pharmaceutical industries, this modular system provides the flexibility needed to optimize residence time, shear, and mixing intensity.

1. Parallel Twin Screw:

Configuration:

This means two screws run side-by-side within the barrel.

Crucially, these screws can be co-rotating (spinning in the same direction) or counter-rotating (spinning in opposite directions). Co-rotating is far more prevalent in polymer processing.

Function:

Twin screws provide excellent mixing, conveying, and pumping capabilities.

Parallel co-rotating screws are particularly effective at:

Compounding: Blending polymers with additives, fillers, and other materials.

Reactive extrusion: Facilitating chemical reactions during processing.

Precise material transport.

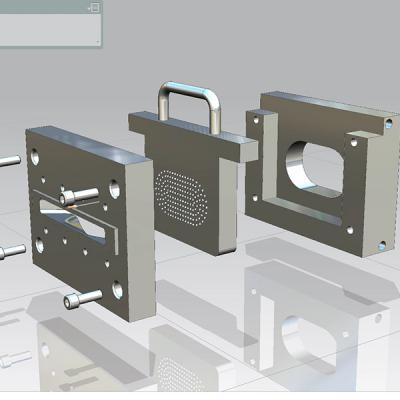

2. Block Type Barrel:

Modularity:

The barrel is constructed from individual, interchangeable sections or "blocks."

This allows for:

Customization: Barrels can be configured to match specific process requirements.

Flexibility: Changes to the process can be accommodated by rearranging or replacing barrel sections.

Maintenance: Damaged sections can be easily replaced, minimizing downtime.

Function:

The barrel provides a containment and temperature-controlled environment for the screws and the material being processed.

The modular design allows for the incorporation of features like:

Side feeders: For adding materials at specific points along the barrel.

Venting ports: For removing gases or moisture.

Liquid injection ports: For adding liquids.

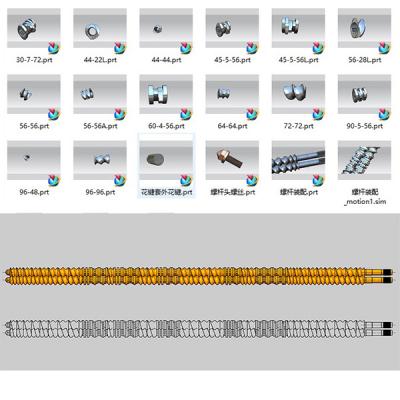

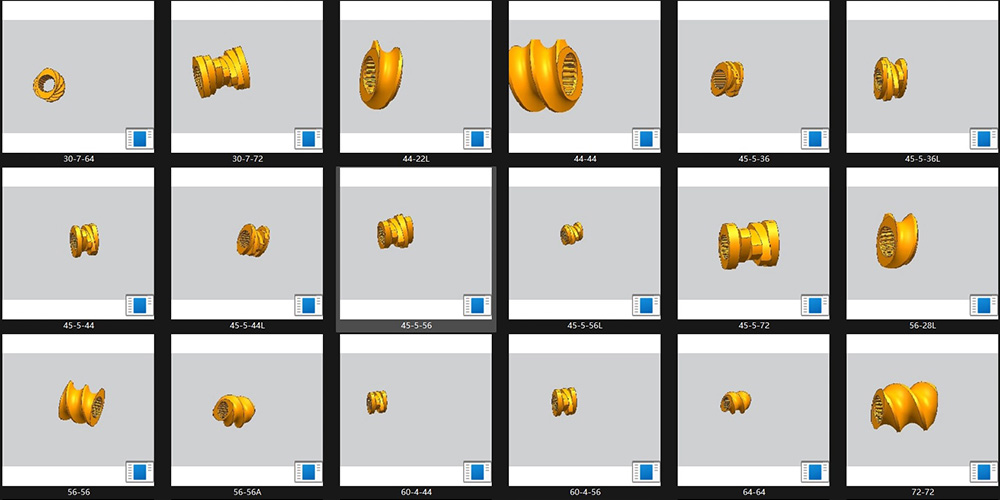

3. Screw Elements:

Modular Screw Design:

Similar to the barrel, the screws are assembled from individual screw elements.

These elements can include:

Conveying elements: For moving material along the barrel.

Kneading blocks: For intensive mixing.

Mixing elements: For distributive and dispersive mixing.

Overall Significance of a block type parallel Twin screw extruder:

Overall Significance of a block type parallel Twin screw extruder:

Versatility:

Block-type parallel twin-screw extruders are highly versatile machines capable of processing a wide range of materials.

They are widely used in the plastics, food, and pharmaceutical industries.

Process Control:

The modular design and precise control of processing parameters allow for highly controlled and consistent product quality.

Efficiency:

Twin-screw extruders offer high throughput and efficient processing.

This type of extruder is a sophisticated and adaptable tool for complex material processing.

Key Features:

Modular Screw Elements: Fully customizable screw shafts utilizing interchangeable conveying elements, kneading blocks, and specialized mixing elements to suit specific material requirements.

Segmented Barrel Design: The barrel is constructed from individual, high-strength blocks, allowing for the strategic placement of side feeders, vacuum venting ports, and liquid injection sites.

Parallel Co-rotating Configuration: Optimized for superior distributive and dispersive mixing, ensuring consistent product quality and high throughput.

Durable Construction: Manufactured from premium alloy steel (e.g., 38CrMoAlA) with advanced surface treatments for exceptional wear and corrosion resistance.

Ease of Maintenance: Individual segments can be replaced or rearranged without replacing the entire assembly, significantly reducing downtime and long-term costs.