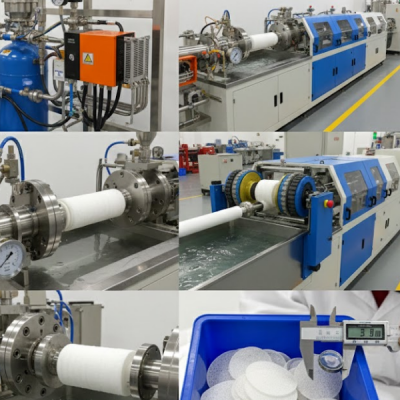

HDPE Foam Extrusion Production Line

This production line is a high-precision, automated system designed for the physical foaming of polymers such as PE, PS, PP, TPU, PLA, and EVA. It is particularly optimized for producing biochip filter media, sealing strips, and specialized foamed profiles using a patented Supercritical CO2 Injection System.

Developed by our specialized R&D team, the RG90 Production Line integrates our proprietary, patented Supercritical CO2 Injection System with advanced extrusion technology. This innovative system is designed for the one-step physical foaming of strips, rods, and sheets. It serves diverse industries, including eco-friendly filtration, door/window sealing, cushions, and automotive gaskets. Featuring precision electrical controls, high automation, and stable performance, the line offers an environmentally friendly, pollution-free process that requires minimal labor (only 2 operators per shift).

Scope of Supply

The complete production line includes the following components:

Item Description Specifications/Capacity

1 Stainless Steel Mixer 500 kg capacity

2 Automatic Feeder Vacuum/Screw feeding

3 RG90 Primary Extruder Output: 40–80 kg/h; Solenoid auto-cooling

4 Co-extrusion Head & Die Includes 1x 6kW Oil Temperature Controller

5 Stainless Steel Cooling Tank Full set

6 Air Wipe/Drying System For moisture removal

7 Caterpillar Haul-off Machine Belt-type traction

8 CO2 Injection System Patented

9 Integrated Control Cabinet Combined electrical control

10 RG65 Envelopment Extruder Output: 10–40 kg/h (For outer skin coating)

11 Spare Parts Kit Included(only we think it's necessary)

12 Technical Documentation Manuals and schematics

RG90 Supercritical CO2 Foaming Extruder

Screw & Barrel: 38CrMoAl high-grade alloy steel.

Gearbox: National standard 225 hard-tooth surface reducer.

Main Motor: 45kW motor with vector variable frequency control.

Heating System: 32kW energy-saving heater.

Cooling System: Stainless steel cooling loops with solenoid valve-controlled automatic water cooling.

Control: PID automatic temperature control via precision electrical cabinet.

RG65 Envelopment (Skin Coating) Extruder

Purpose: Applying the dense outer "Envelopment" layer.

Motor: 7.5kW with vector variable frequency speed regulation.

Heating: 10kW electric heating system.

Downstream Equipment

Co-extrusion Die: Crafted from high-quality mold steel; Includes a 6kW Oil Temperature Controller for high-precision thermal management.

Haul-off: Caterpillar-style traction for consistent pulling speed.

Slicing Machine: Precision cutter for finishing (e.g., "Bio-chip" production).

Utility Requirements (User Responsibility)

Power: 3-Phase, 4-Wire, 380V, 50Hz. Total installed capacity: 116kW (Actual consumption: ~40kW/h).

Circulating Water: Must be Soft Water or Purified Water to prevent scaling.

Requires constant temperature, constant flow, and 2–4 kg pressure.

Consumables: 50kg of antifreeze and lubricating oil.

Gas Supply: CO2 cylinders or storage tanks.

Environment: The workshop should maintain a constant ambient temperature.