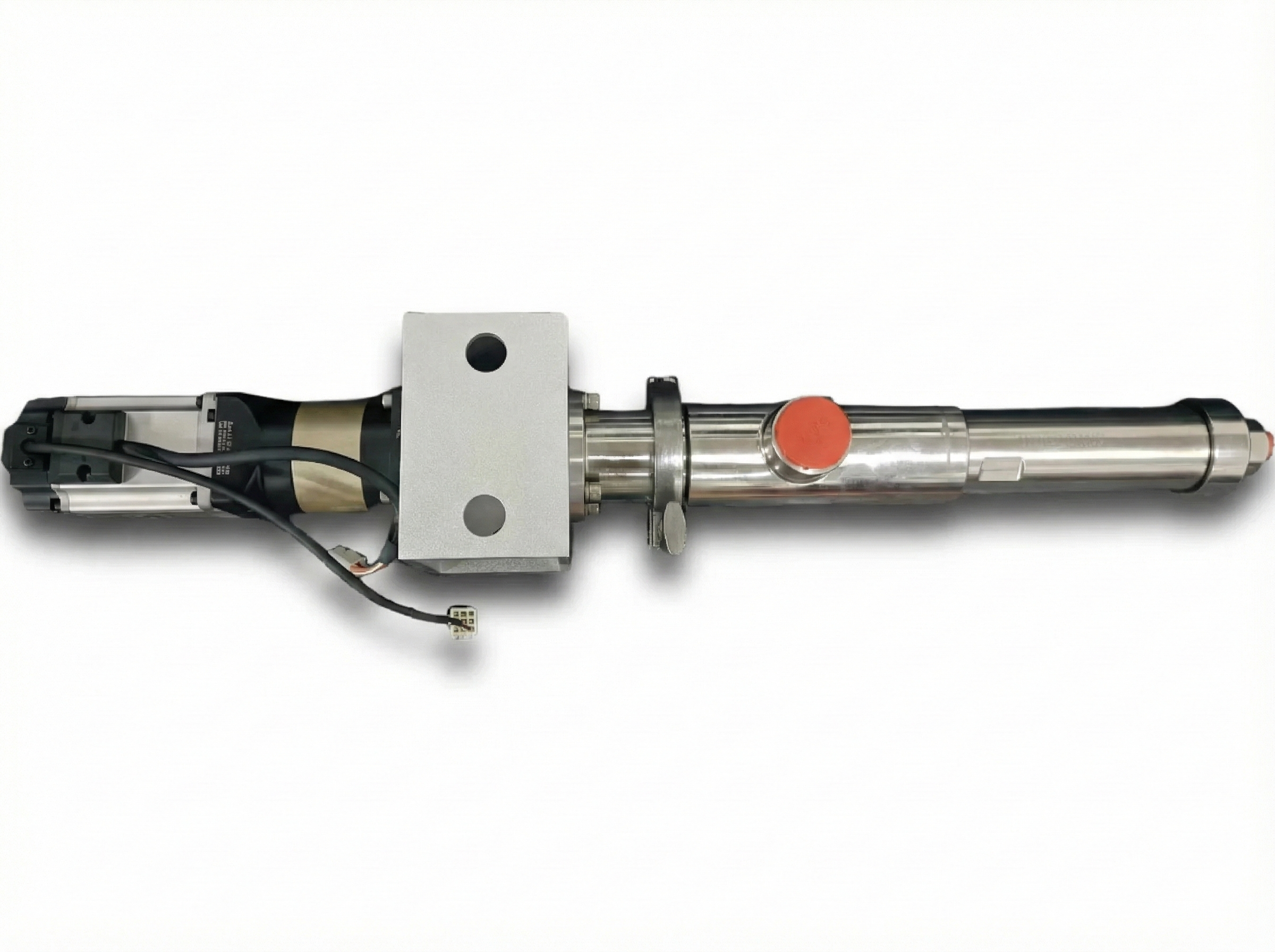

Motorized screw type displacement pump

RoNice is a compact, lightweight, general-purpose model that can be installed on various types of robots, including Cartesian coordinate robots or SCARA robots.

Static mixing tube

Applicable Liquid

Silicone resin, epoxy resin, UV cure resin, Silicone oil, anti carburization agent, lubricant, etc

Can be used for dispensing of glue or 3D Printing of chocolate?

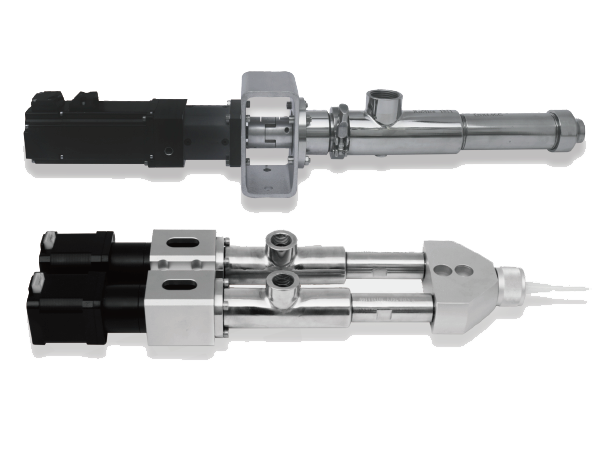

RDGscrewpump integrated stepper controller POT or Pulse n Direction dual mode controllable stepper motorized screw pump

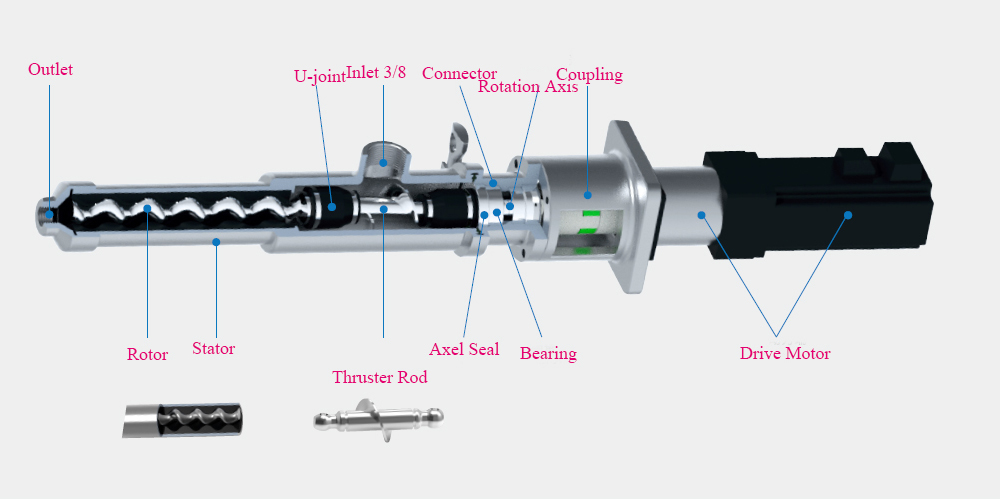

The metering and filling screw pump can be driven by nema17, nema23 stepper motor, geared stepper or servo motor which is designed for the industry of glue, chemical, pharmaceutical and other industries with high viscosity. It's for accurately dosing or filling and metering, its structure is fully suitable for smooth and low pulsating transmission medium, corrosive and anti-corrosion chemicals.

Max pressure 24 bars, 0.75CC 1.5-15.5L/H 200W Servo Motor or NEMA17/NEMA23 geared stepper motor

Screw Pump Notice

There are kinds of materials for the screw pump, aluminum, stainless steel or Ceramic, etc. To clean the stainless steel screw pump or during usage, 84 liquid or other chloride-containing liquid is Not recommended. Alcohol is recommended for cleaning the screw pump.

Important Warnings (What NOT to do)

❌ NO Chlorine/Bleach: The manufacturer explicitly states: "84 liquid or other chloride-containing liquid is NOT recommended." It will corrode the stainless steel rotor.

❌ NO Dry Running: Never run the pump without liquid/material inside for more than a few seconds. The friction generates heat instantly and will burn the rubber stator.

❌ Watch for "Cooking": If using hot water to clean starch, ensure it isn't too hot, or the starch might gelatinize (turn into a rubbery solid) inside the pump before it flushes out.

Servo motorized screw pump

LNX Series (Output Shaft 80 Flange)

Features: Exquisite overall design with a total length equal to the B series but with a smaller pump flange. It features an enlarged bearing to improve axial force and load capacity. The seal uses corrosion-resistant PTFE to withstand increased pressure and temperature ranges.

Application: Suitable for matching with 60 and 80 series servo deceleration motors; easy to install on platforms or inside machines.

Specifications:

Flow Range: 3.0-270 L/H.

Pressure Range: 0-2.4 Mpa or higher.

Models: LNX1.5CC, LNX3CC, LNX6CC, LNX12CC, LNX24CC.

NOTE: To handle mixture (Water + Starch + Abrasive Fibers), just like in plastic extrusion, the Rotor (Screw) needs surface hardening to survive the fibers.

1. Rotor (Screw) Material: We cannot use standard Stainless Steel (SS304/316) as it will wear too fast. Please quote for:

Option A (Best): Solid Ceramic Rotor (Zirconia or Alumina).

Option B (Common Industrial): Tungsten Carbide Coating (or Hard Chrome Plating if WC is not available).

Note: Nitrided steel is acceptable, but we prefer Tungsten Carbide for wet abrasion.

2. Stator Material (Critical): Since the fibers will cut into the rubber, we need a high-wear resistant elastomer.

Please recommend a High-Abrasion Resistant NBR or similar material suitable for fiber slurries.