Professional Guide: Maximizing Performance of Miniature Linear Rails (Beyond the Myths)

At RobotDigg, we know that many users try to "hack" or modify budget linear rails to improve their smoothness. A common practice found on hobbyist forums involves washing out factory grease, swapping carriages, or reaming channels.

However, treating a precision component like a DIY project often leads to degraded performance. To get the best results from your miniature linear guides (MGN series), you must follow scientific engineering standards, not "rule of thumb" hacks.

Here are the four critical rules for handling and maintaining linear rails correctly.

1. Scientific Preload Requires a Reference Surface

The Myth: "I held the rail in my hand and moved the carriage. It felt tight/gritty, so the rail is bad." The Reality: A linear rail is flexible. It is not a structural beam. When you hold a rail in the air, it twists and bows slightly, causing the internal balls to bind against the raceway.

The Physics: Linear guides are designed to conform to the straightness of the surface they are mounted to. The internal preload (the tension on the balls) cannot be accurately judged until the rail is straightened by mounting bolts.

The Rule: Your testing practice is not scientific unless the rail is fixed.

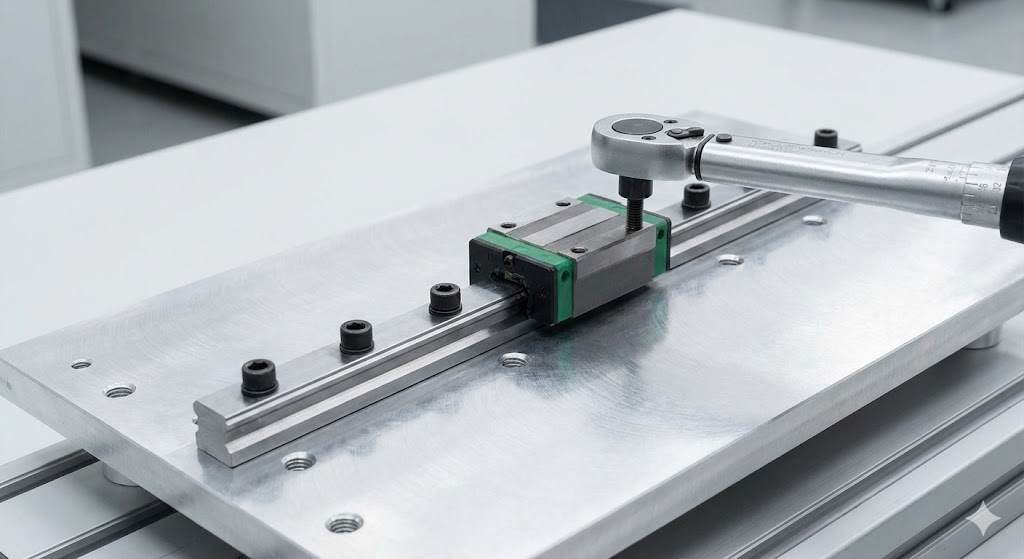

Mount the rail to a flat, machined reference surface.

Tighten bolts (center-out).

Then test the carriage for smoothness.

2. Carriages Are Not Interchangeable (Matched Pairs)

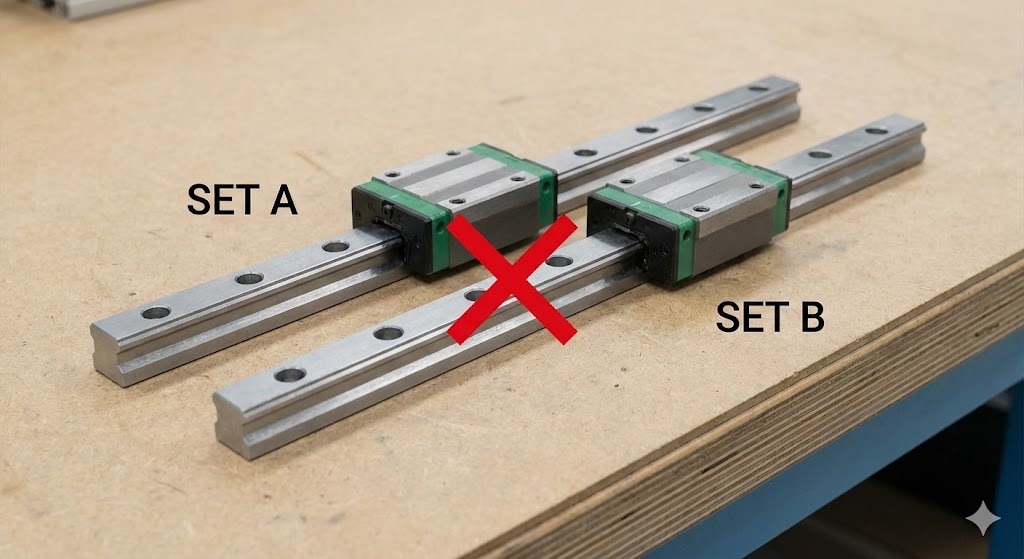

The Myth: "I can buy a spare carriage block and throw it on my existing rail." The Reality: In precision engineering, the carriage block and the rail are often a matched set. They are ground to specific tolerances to achieve the correct clearance (Z0) or preload (Z1).

The Risk: Swapping a carriage from one rail to another often results in "slop" (wobble) or excessive binding.

Transport Warning: Because the fit is so precise, the bearing balls can suffer from "collision" during transport if the carriage slides uncontrolled into the end-stops.

The Rule: Never mix and match blocks and rails. Ensure the carriage is secured during shipping to prevent impact damage.

3. Zero Tolerance for Contamination

The Myth: "I should disassemble the block to polish the channels." The Reality: Miniature rails have extremely tight tolerances. A single particle of dust, a grain of sand, or a lint fiber inside the block acts like a rock in the raceway.

The Consequence: Debris creates a gritty feel that many users mistake for bad machining. Over time, this debris causes spalling (flaking) of the hardened steel rails.

The Rule:Do not disassemble the carriage block unless absolutely necessary.Ensure no foreign objects enter the guide groove during assembly.Use the provided plastic caps to cover rail mounting holes so debris does not settle there.

4. The Truth About "Sticky" Grease

The Myth: "The factory grease is just sticky shipping glue. You should wash it out and apply light oil." The Reality: For high-quality miniature rails, the lubricant inside is not shipping glue. It is likely Kyodo Yushi Multemp PS No. 2 (RobotDigg stainless steel linear rail and carriage factory applied option which is same with IKO or THK).

Why it matters: This is the industry-standard factory choice. It is a synthetic lithium soap-based grease specifically engineered for low-temperature, low-torque precision rolling elements.

The Error: Many users confuse the natural viscosity of this high-grade grease with "stiction." Replacing it with thin machine oil (like sewing machine oil) destroys the film strength required to protect the raceways under load.

The Rule: Do NOT apply heavy generic automotive grease (which causes drag), but do NOT wash out the specific factory grease (PS No. 2). It is designed to be there.

Summary

To get the best performance from your RobotDigg linear rails, respect the engineering:

Trust the Factory Grease: PS No.2 is the factory.

Mount Before Judging: Do not test rails "free-floating" in your hands.

Keep Sets Together: Do not swap carriages.

Keep it Clean: Prevent dust entry and avoid disassembly.

Recent post:

- Why Agglomerated Plastic Pellets Fail in Film Production: The Necessity of Secondary Re-Extrusion

- From Field Waste to Factory Floor: The Twin Revolutions in Sustainable Materials

- Shredder Knife Material Comparative Analysis: 75Cr1, 9CrSi, and H13

- RobotDigg Components Power 1st Place IAAPA Award-Winning Game!

- Dexterity Hands Industry Report: The Democratization of Robotic Manipulation