Why Agglomerated Plastic Pellets Fail in Film Production: The Necessity of Secondary Re-Extrusion

At RobotDigg, we often encounter manufacturers, like our recent client from Australia, who attempt to use plastic granules produced by a low-temperature cold pelletizing machine (specifically, an Agglomerator or Compactor) directly for high-precision applications such as blown film or film casting.

The result, invariably, is failure.

It's crucial to understand that while the agglomerator is an essential piece of equipment in film recycling, the product it creates is merely pre-processed feedstock, not a finished pellet ready for manufacturing. To successfully transform plastic waste into a viable film, an indispensable intermediate step—Secondary Hot-Melt Granulation (Re-extrusion)—is required.

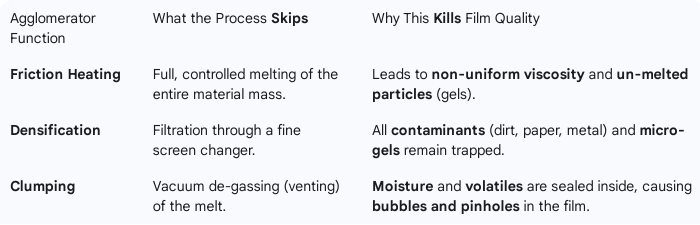

1. The Critical Flaw: What the Agglomerator Misses

The low-temperature process of an agglomerator is optimized for densification, not purification. Its goal is to take light, bulky scrap (like film and bags) and convert it into heavy, feedable lumps.

2. Why Film Blowing Demands Higher Purity

Blown film extrusion is arguably the most demanding plastic process. It relies on the polymer melt maintaining a delicate balance of viscosity and strength to form and hold the film bubble. Any instability leads to immediate failure.

A. The "Gels and Specks" Problem

Contaminants—whether foreign inorganic particles or cross-linked polymer domains known as gels—create weak points in the melt. In a process where the polymer is stretched to thicknesses often less than 20 microns, these defects:

Rupture the Bubble: Leading to a total line shutdown.

Cause Pinholes: Ruining the barrier properties and strength of the final film.

Create Die Lines: Impurities accumulate at the die lip, causing persistent lines or streaks that render the film aesthetically and functionally unusable.

B. The Moisture & Volatile Problem

If the agglomerates contain residual moisture or VOCs, these compounds will flash into gas upon reaching the high temperatures of your blown film extruder. This results in:

Foaming and Bubbles: Severely compromising film clarity and strength.

Molecular Degradation: For polymers like PET, residual moisture causes hydrolysis, chemically breaking the polymer chains and destroying the melt strength required to pull and hold a stable film bubble.

3. The Solution: The Mandatory Re-Extrusion Step

The only way to bridge the gap between low-quality agglomerates and film-grade resin is through a second, comprehensive melt processing step: Secondary Hot-Melt Granulation.

This process, performed on a dedicated recycling extruder (often a powerful single-screw or twin-screw setup), achieves the following essential functions:

High-Pressure Melting & Filtration: The material is fully melted, and the flow is forced through a fine-mesh screen changer (e.g., 80 to 120 microns) to physically strip out all trapped gels and solid impurities.

Vacuum De-gassing: The extruder utilizes a strong vacuum pump at the vent port to flash off and remove moisture and all volatile components, stabilizing the polymer for film use.

Homogenization and Stabilization: The screw's high shear action ensures the polymer is thoroughly mixed, guaranteeing a uniform Melt Flow Index (MFI) and consistent color, which are non-negotiable for stable film blowing.

Final Pellets: The purified, stable melt is cut into uniform, consistent pellets, ready for reliable feeding into the final blown film machine.

For RobotDigg's clients, this re-extrusion step is not optional—it is the difference between a load of unusable waste and a valuable, high-quality recycled film product. Always treat agglomerated material as a feedstock, not a final resin.

Recent post:

- The relationship between three common closed-loop modes and FOC control

- Transforming Waste into Value: The Powerhouse Machines of the Plastic Industry

- A Tale of Two Films: Calendering vs. Casting

- The Future of Motion Control: Integrated Linear and Rotary Actuators

- Low-Temperature Cold-Pelletized Recycled Plastic Granules are Not Suitable for Direct Processing