Shredder Knife Material Comparative Analysis: 75Cr1, 9CrSi, and H13

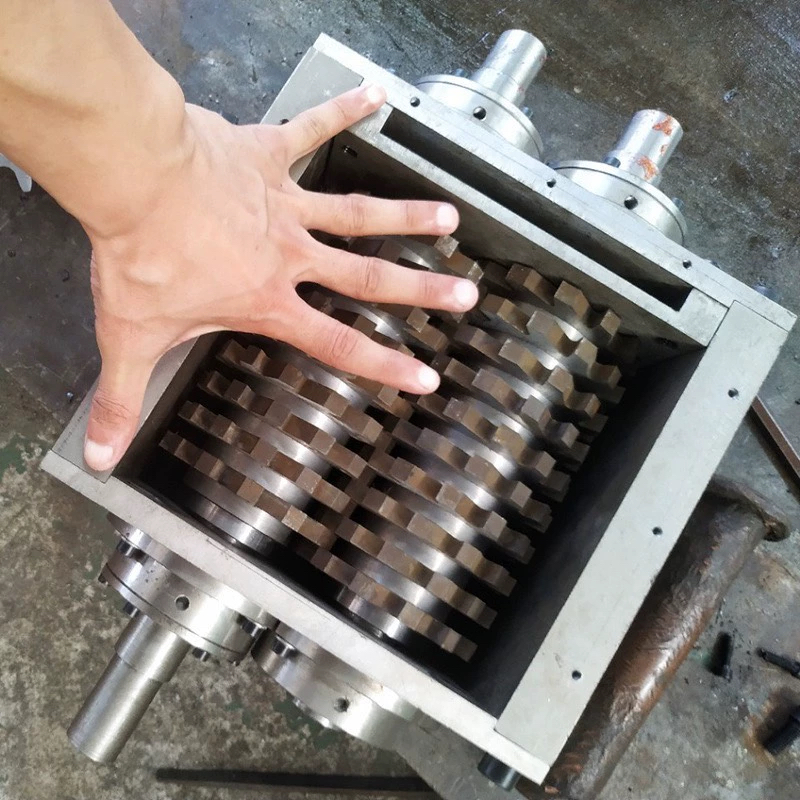

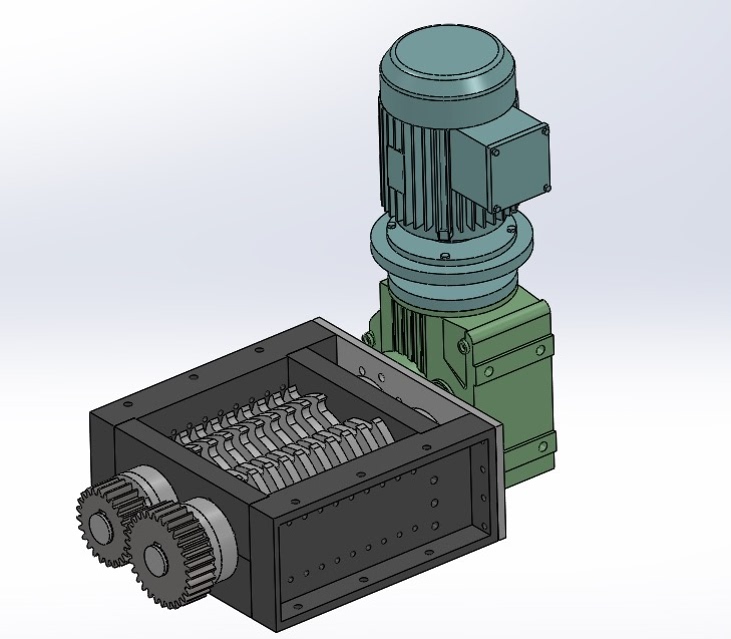

RobotDigg is a provider of robotics, 3D printing components (like motors and linear motion systems), and also offers smaller, desktop-scale shredders and recycling machines, particularly for plastics, we know that the knives are the core of the equipment, and the choice of their material directly determines the machine's efficiency, lifespan, and maintenance costs. Below is a professional comparative analysis of three common or potential knife materials—75Cr1, 9CrSi, and H13—designed to guide selection decisions under various applications and operating conditions.

75Cr1 is an alloy carbon tool steel that, with its moderate carbon content (≈0.75%) and low alloy composition, offers excellent toughness and elasticity.

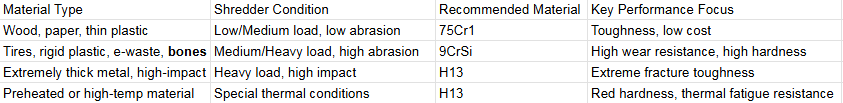

Applicability Analysis: It is best suited for processing wood, paper, thin plastics, and other low-density materials with low impact loads. Its good impact resistance prevents chipping or breaking when subjected to sudden loads or light foreign object impacts.

Limitation: The wear resistance of 75Cr1 is relatively low. When processing highly abrasive materials like fiberglass, sandy plastics, or metals, the knife lifespan will be significantly reduced, requiring frequent replacement or resharpening.

Summary: 75Cr1 is a cost-effective and versatile knife material, suitable for applications where wear resistance is not critical, but knife toughness and resistance to chipping are necessary.

9CrSi: The King of High Hardness and Cold Work Wear Resistance

9CrSi is a classic cold work tool steel, widely used in the shredder industry due to its high carbon, high silicon, and medium chromium composition, making it one of the main knife materials.

Applicability Analysis: 9CrSi possesses extremely high hardness and wear resistance, making it ideal for processing scrap tires, rigid plastics (e.g., PE/PP blocks), e-waste, bones and light metals—materials that cause significant knife wear. The high hardenability ensures uniform performance throughout thicker knife sections.

Advantage: The excellent wear resistance significantly extends the lifespan of the knives and reduces downtime for maintenance.

Limitation: While its toughness is better than some other high-alloy tool steels, it is still lower than 75Cr1. There is a risk of chipping when processing extremely hard, highly impact-loaded metals (such as thick steel plates or large solid shafts).

Summary: 9CrSi is the optimal choice for balancing performance and cost, suitable for the vast majority of medium to high-intensity shredding tasks.

H13: For Special Hot Applications and Extreme Toughness Needs

H13 is a Chromium-Molybdenum-Vanadium hot work tool steel, primarily designed to resist high temperature, high stress, and thermal shock.

Applicability Analysis: H13 is less common in conventional shredders but is highly suited for special operating conditions:

High Impact Conditions: Certain large, low-speed, heavy-duty shredders require knives with extremely high fracture toughness to resist extreme impact loads. H13's toughness at moderate hardness far surpasses 9CrSi.

Hot Shredding Conditions: If the material needs to be preheated to a high temperature (e.g., certain special plastics or asphalt materials) before shredding, H13's red hardness (ability to maintain hardness at high temperatures) is irreplaceable.

Limitation: At room temperature, H13's wear resistance is inferior to high-hardness 9CrSi. To achieve the required toughness, H13's working hardness is typically lower than 9CrSi, leading to a relatively faster wear rate.

Summary: H13 is a specialized material choice, only recommended for niche applications requiring extreme impact or high temperature shredding, trading off some wear resistance for the highest anti-fracture performance.

Final Decision: 9CrSi is the most widely used and well-balanced performance material for shredder knives. Engineers must comprehensively evaluate the material's hardness, abrasiveness, impact load, and presence of contaminants. When necessary, consider coating the knives with hard alloys or ceramics to further enhance performance.

Recent post:

- A Tale of Two Films: Calendering vs. Casting

- The Future of Motion Control: Integrated Linear and Rotary Actuators

- Low-Temperature Cold-Pelletized Recycled Plastic Granules are Not Suitable for Direct Processing

- Why Agglomerated Plastic Pellets Fail in Film Production: The Necessity of Secondary Re-Extrusion

- From Field Waste to Factory Floor: The Twin Revolutions in Sustainable Materials