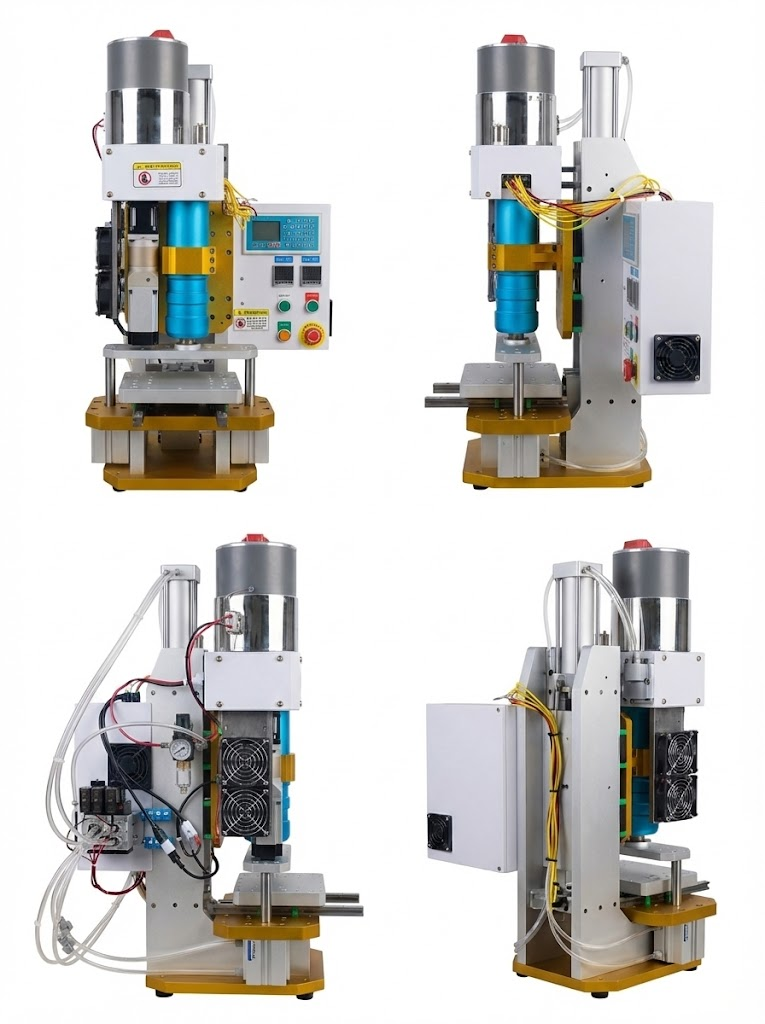

Low-pressure encapsulation injection molding

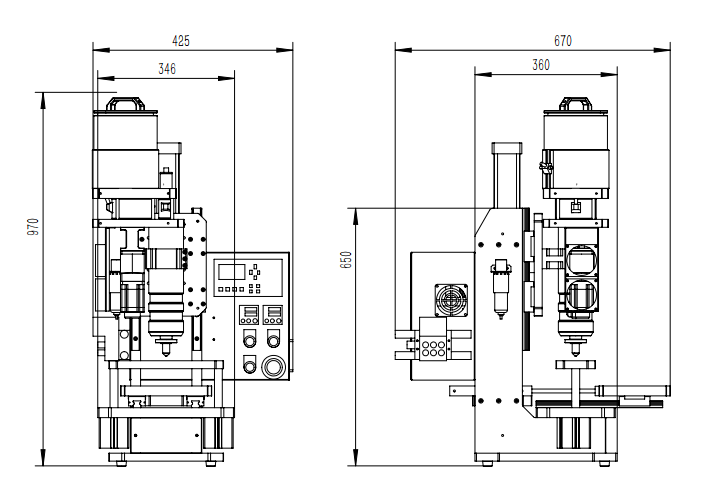

Machine Size: 425mm*670mm*970mm

Machine weight: 95 kg

Electricity: AC220V 50Hz

Air pressure required: 0.5 MPa

Temperature control: 2 zones

Temperature range ambient up to 250°C

Mold set size: 40*180 H150

Melting Tank:2.5L

Max. power: 3 Kw

Ejector force: 1.5-40bar

Clamping stroke: 100mm

Range of Materials: Polyamide hot melt adhensive

Low-pressure injection molding method is ideal for small, intricate parts that require precise molding without damage. The "low pressure" technique minimizes stress on the plastic, crucial for delicate features and connections.

The offer to sample before full production is a major plus. It allows you to evaluate part quality, functionality, and minimize financial risk as you only pay for the mold initially.

Before deciding, carefully consider the overall cost, including mold costs, sampling fees, and production costs. Investigate the machine's capabilities, the supplier's reliability, and inquire about lead times.

This low-pressure injection molding machine excels at encapsulating delicate components like connectors and sensors using polyamide hot melt adhesive. The gentle process minimizes stress, ensuring precise molding without damage.

To aid your investment decision, we offer a sampling service. You can obtain physical samples to evaluate the quality, fit, and finish for a modest mold cost. This allows you to assess the machine's suitability for your specific application before committing to a full production run.

Key benefits include precise encapsulation, minimal stress on components, a wide range of applications, and the cost-effectiveness of the sampling service. This machine is ideal for applications requiring high precision and component protection.

Desktop Low-Pressure Injection Molding Machine

Features:

Low-pressure injection: Utilizes low-melting-point granular polyamide material and low-pressure injection molding.

Large capacity: 1-liter glue pot with a Teflon-coated interior.

Precise dosing: Active needle valve prevents leakage.

High precision: Servo motor ensures shot weight accuracy within ±0.3 grams.

Versatile: Suitable for encapsulating various sensors, connectors, and circuit boards.

Advantages of Servo-Driven Injection:

Superior performance compared to pneumatic injection systems.

Applications:

Ideal for encapsulating electronic components such as sensors, connectors, and circuit boards.

This desktop machine is designed for precise and efficient encapsulation of small electronic components. Its low-pressure injection system, coupled with a servo motor, ensures accurate dosing and minimizes damage to delicate parts. The machine's versatility and ease of use make it a valuable tool for a wide range of applications.

Over molding

Insert molding

Although the RobotDigg LP2501 is explicitly marketed as a "Desktop low pressure encapsulation injection molding machine" designed for Polyamide (PA) hot melt adhesives, there are other materials in the Low Pressure Molding (LPM) industry that are physically similar and use comparable processing methods.

Based on this machine's specifications (heated tank, max 250°C, low injection pressure), here are the material categories that are theoretically suitable or similar:

1. Polyolefin Hot Melt Adhesives (PO) — The Primary Alternative

This is the most common alternative to Polyamide in the low-pressure molding industry.

Comparison:

Polyamide (PA): Strengths include high heat resistance, mechanical strength, and excellent adhesion to various substrates (PCBs, metals). The downside is higher moisture absorption.

Polyolefin (PO): Strengths include excellent moisture/water resistance (very low water absorption) and better adhesion to "difficult-to-bond" plastics (like PP or PE housings).

Suitability:

Usually supplied in granule form.

Melting points and viscosity ranges generally fall within the machine's capabilities (typically 180°C - 220°C).

Crucial Note: You cannot mix PO and PA materials. If you plan to switch materials, the melting tank must be thoroughly purged and cleaned, as mixing them at high temperatures can cause chemical reactions or carbonization, clogging the needle valve.

2. Copolyester Hot Melt Adhesives (PES)

Characteristics: Offers very good chemical resistance and heat resistance, with excellent electrical insulation properties.

Suitability: Primarily used where resistance to chemical corrosion is required. Processing temperatures are usually between 200°C - 240°C, fitting the LP2501's heating range.

3. Thermoplastic Elastomer (TPE/TPR) or Polyurethane (TPU) Hot Melts

Characteristics: These materials cure to a rubber-like elasticity, offering a softer touch and better impact/shock absorption.

Suitability:

Used for flexible cable strain reliefs or "soft-touch" overmolding.

Warning regarding Viscosity: You must verify that the material's viscosity is low enough. Low-pressure molding relies on materials that flow very easily (like syrup). If the TPU viscosity is too high (like standard injection molding TPU), this machine's low pressure (0.5 - 5 MPa range) will not be able to fill the mold.

Critical Technical Warnings

While the materials above are physically similar (hot melt granules), you must pay attention to the following when using the RobotDigg LP2501:

Viscosity Constraints: The machine is designed for "Polyamide," which becomes extremely fluid when melted (low viscosity). Standard injection molding plastics have high viscosity. If you use a material not specifically formulated for Low Pressure Molding (LPM), you risk under-filling molds or damaging the machine's pump/motor.

The "PUR" (Reactive Polyurethane) Danger Zone: Do NOT use PUR (Polyurethane Reactive) hot melt adhesives in this machine unless you have a strict cleaning protocol. PUR cross-links and cures chemically (turning into a solid, stone-like state) if left heated in the tank. The LP2501's tank design is likely not suitable for PUR, and using it could permanently ruin the melting tank and injection head.

Sourcing Advice: If looking for non-PA materials, specifically search for "LPM specific grades" (Low Pressure Molding grades) from major suppliers. Examples include:

Henkel: The Technomelt series (includes both PA and PO bases).

Bostik: The Thermelt series.

Summary Recommendation: The safest "similar material" is LPM-grade Polyolefin (PO). It offers better waterproofing than Polyamide and uses similar processing parameters. However, before switching, check with the supplier regarding the machine's viscosity limits and cleaning procedures.