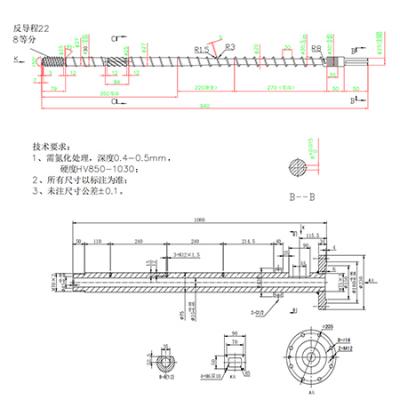

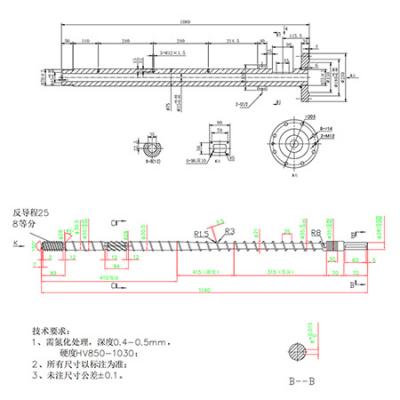

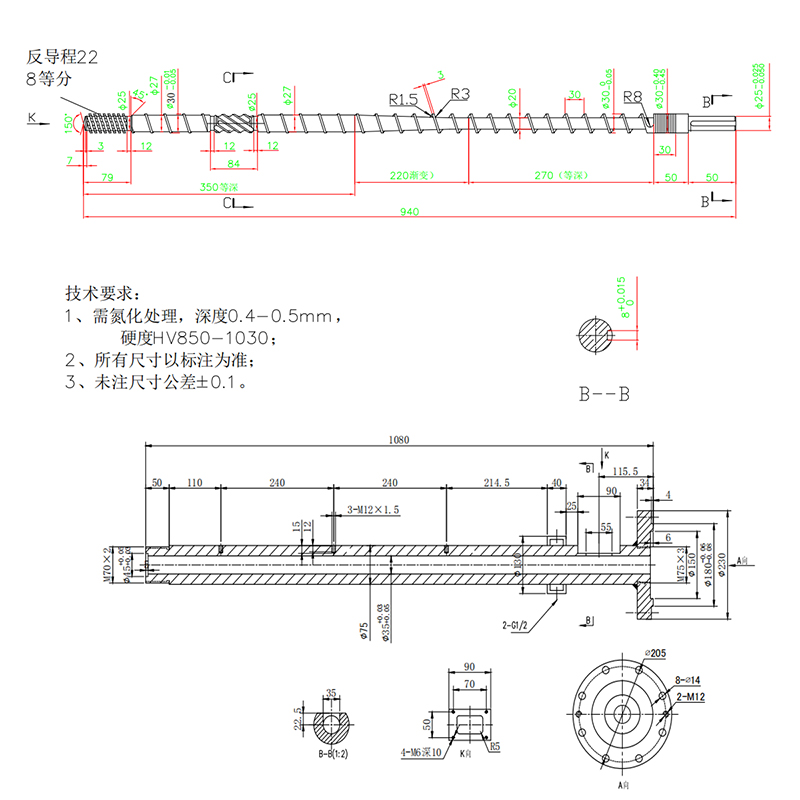

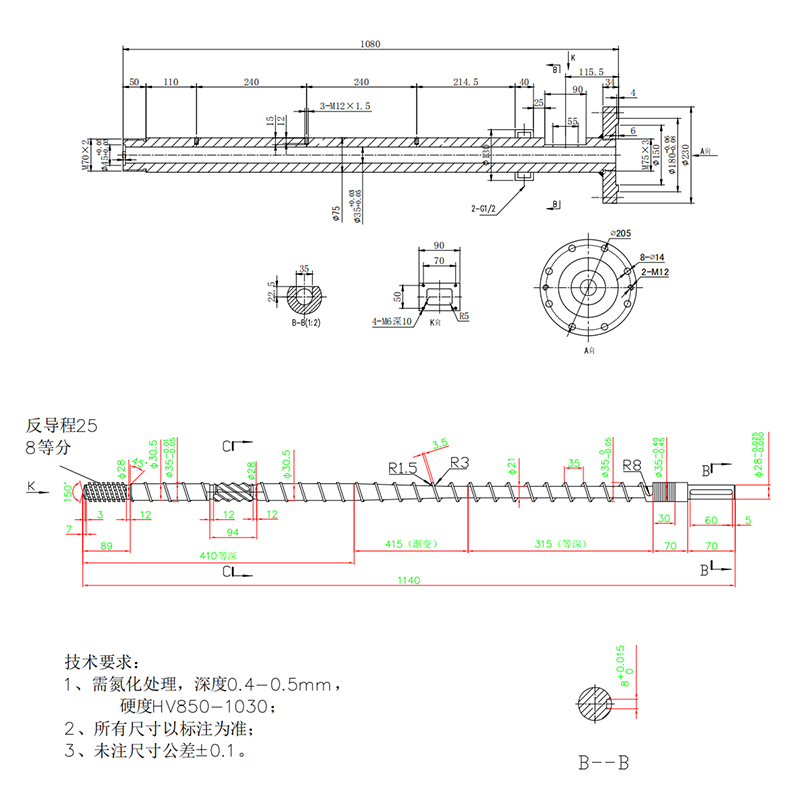

D30 and D35 screw with mixing and shearing sections

Length diameter ratio 28, D30, and D35 screw with mixing and shearing sections.

Screw 38CrMoAlA Nitried and Plated

1. HPT fully hardened powder alloy screw

The tungsten-cobalt powder alloy tool steel is used, which is integrally hardened by a special process. The overall hardness of the inside and outside of the screw is the same, reaching about HRC65°. It is suitable for processing all kinds of transparent products, precision products, and LCP, PPS, PES, PPA, and other special high-temperature and highly corrosive plastics with added fibers.

2. Double alloy screw

SACM645, 38CrMoAlA is used as the base material, and then the tooth crest or screw groove is ion-spray-welded with tungsten carbide-nickel-based alloy, and the surface hardness of the screw is about HRC60°. It is suitable for processing various transparent products and engineering materials such as PA6 and PA66 with added fibers.

3. Electroplating screw

SACM645 and 38CrMoAlA are used as the base material, and the outer surface is electroplated with a layer of hard chromium, nickel, titanium, and other elements after molding. The hardness is around HRC60°. Suitable for processing PC, PMMA, PET transparent materials, and corrosive plastic U-PVC materials.

4. Stainless steel screw

The material is 9Cr18MoV special stainless tool steel, which adopts overall quenching + overall hardening treatment, and the overall hardness is about HRC55°.

5. SKD61 screw

Using Hitachi SKD61 material, processed by a special process, the product has good toughness and strong torsion resistance.

6. Ordinary nitriding screw

SACM645 and 38CrMoAlA are used as the base material and formed by special processing, the depth of the nitride layer is 0.5-0.8mm, and the overall hardness is HV980~1080°. Suitable for processing ordinary plastics, such as PP, ABS, PS, AS, PVC, and other common plastics.