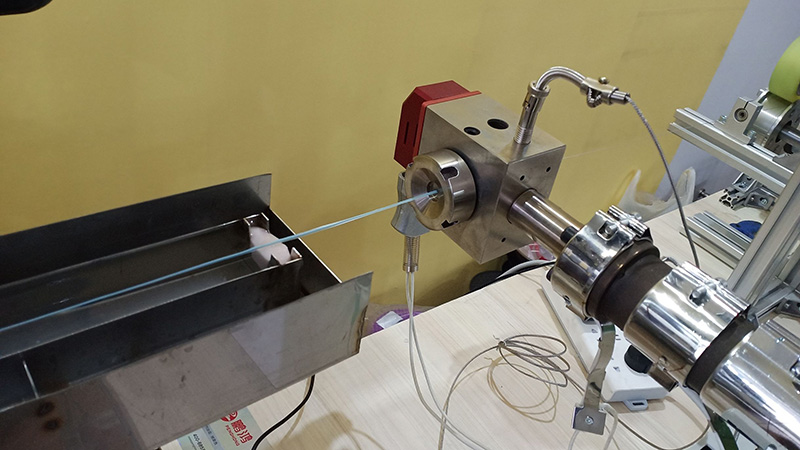

Desktop nose wire coating extrusion line

PPE personal protective equipment? Below is all for Laboratory. Desktop production line for melt-blown fabric extrusion and nose wire extrusion.

The desktop SJ25 extrusion line with special Customized DIE is for single metal core nose wire or full plastic nose wire production

Automatic equipment to extrude medical mask nose clipping (bridge) wire as per PPE (Personal Protective Equipment) request during COVID-19 outbreak the pandemic.

The Nose Wire is used for disposable face masks.

There are kinds of nose wire for different face masks, N95 or KN95 use aluminum nose wire, plastic nose wire PE, single metal core nose wire with plastic coating of PE.

This SJ25 extrusion line can also be used for wire cable coating of plastic for mouse or other kinds of cables with metalcore.

Melt-blown nonwoven or cloth for respirator vertical extrusion line is coming soon.

The extrusion production line is suitable for precious plastic projects as well, metalcore PE coated wire can be used to weave basket-like Customers in China.

Plastic wire coating extrusion

Plastic wire coating extrusion is the continuous process of applying a molten plastic insulation or jacket around a bare wire or cable core. Unlike other forms of extrusion where the plastic forms the entire shape (like a pipe), here the plastic is a skin applied over a moving substrate.

The following guide details the machinery, the critical "tooling" techniques, and the common materials used in this process.

1. The Extrusion Line: Step-by-Step

A wire coating line is a synchronized system where speed and temperature must be perfectly balanced.

Stage Component Function

1. Entry Pay-off Unwinds the bare wire or core from a reel or drum. It must maintain constant tension to prevent the wire from jerking.

2. Prep Pre-heater Heats the copper/aluminum wire before it enters the plastic. Why? Cold wire sucks heat out of the plastic too fast, causing poor adhesion and internal stress.

3. Melting Extruder A screw inside a heated barrel melts plastic pellets. It pushes the molten plastic into the Crosshead (see below).

4. Coating Crosshead & Die The heart of the process. The wire passes through this head where the plastic flow turns 90° to cover the wire.

5. Cooling Water Trough A long tank of water that cools the plastic so it hardens. The water temperature is graduated (warm to cold) to prevent thermal shock.

6. Testing Spark Tester A high-voltage bead chain the wire passes through. If there is a pinhole in the insulation, a spark jumps and an alarm sounds.

7. Exit Capstan & Take-up The capstan pulls the wire through the line at a precise speed, and the take-up winds the finished product onto a final spool.

2. The Critical Component: Crosshead & Tooling

The most distinct part of wire extrusion is the Crosshead. The extruder pushes plastic in from the side, and the crosshead splits this flow around the wire (using a "deflector" or "heart-shaped" distributor) to ensure the coating is even on all sides.

Inside the crosshead, you choose between two main types of tooling (Tip & Die) depending on the desired result:

A. Pressure Tooling (Fill & Stick)

Mechanism: The plastic meets the wire inside the die, under high pressure.

Result: The plastic fills all the gaps between the wire strands and sticks tightly to the conductor.

Best For: Primary insulation where you need high dielectric strength and no air gaps (e.g., individual electrical wires).

B. Tubing (Sleeving) Tooling

Mechanism: The plastic is extruded as a hollow tube larger than the wire. As the wire moves faster than the plastic, it pulls (draws down) the tube onto itself like a shrink-wrap.

Result: The plastic forms a loose or semi-tight jacket. It does not fill the gaps between strands.

Best For: Outer cable jackets (sheathing) where you want the cable to be flexible and easy to strip.

Note on Centering: If the wire isn't perfectly in the center of the plastic, you get "eccentricity" (one side thin, one side thick). Modern crossheads use self-centering designs, but many still require manual adjustment of bolts to align the tip and die.

3. Common Materials

The choice of plastic ("compound") dictates the cable's temperature rating, flexibility, and resistance.

PVC (Polyvinyl Chloride): The most common. Cheap, flame retardant, and easy to process. Used for house wiring and power cords.

PE (Polyethylene): Excellent electrical insulator (low dielectric loss). Used for communication cables (coax, Ethernet).

XLPE (Cross-linked PE): PE that is "cured" (often using steam or heat) to become heat resistant. It doesn't melt like standard plastic. Essential for high-voltage power cables.

Fluoropolymers (FEP, PTFE/Teflon): High-performance plastics that withstand extreme heat and chemicals. Used in aerospace and industrial wiring.

4. Common Defects

Eccentricity: The conductor is off-center. Caused by poor die alignment or unstable wire tension.

Spark/Pinhole: A hole in the insulation. Caused by contaminants (dirty pellets) or "melt fracture" (running too fast).

Rough Surface (Sharkskin): The surface looks like orange peel. Usually caused by the melt being too cold or the die being dirty.