Industrial-Grade LFAM: Mastering Glass Fiber and Carbon Fiber with RobotDigg Pellet Extruders

In the world of Large Format Additive Manufacturing (LFAM), the move from standard polymers to composite materials like Glass Fiber (GF) and Carbon Fiber (CF) is not just an upgrade—it is a fundamental requirement. These reinforcements provide the structural integrity, reduced shrinkage, and thermal stability necessary for large-scale industrial parts and furniture, boat, sculpture, etc.

However, these materials are notoriously "abrasive," acting like liquid sandpaper on internal components. To meet this challenge, RobotDigg offers specialized hardware upgrades designed for high-wear continuous operation.

1. The Necessity of Reinforced Materials in LFAM

Standard plastics often suffer from warping and "internal stress" when printed at a large scale. Adding 20% to 40% Glass Fiber significantly increases the mechanical properties:

Reduced Warping: Fibers minimize the Coefficient of Thermal Expansion (CTE).

Increased Stiffness: Essential for load-bearing structures.

Better Layer Adhesion: Improved thermal mass helps layers bond more effectively in large open-air environments.

2. Combatting Abrasion: Tungsten Nitride & Bimetallic Solutions

The main drawback of GF and CF pellets is the rapid wear they cause on standard steel components. A standard barrel can lose its tolerance in a matter of weeks, leading to "backflow" and inconsistent extrusion.

To solve this, RobotDigg provides high-durability options for their Pellet Extruder Kits:

Tungsten Nitride (W₂N) Coating: A super-hard surface treatment that creates a low-friction, high-wear barrier.

Bimetallic Screws & Barrels: These components feature a specialized alloy lining (often containing cobalt or nickel-chrome) that is centrifugally cast inside the barrel to withstand the constant scouring of glass fibers.

Hardened Nozzles: Standard brass nozzles will enlarge their diameter within hours of printing glass fiber. RobotDigg offers hardened steel or specialized alloy nozzles to maintain precise line widths over long-duration prints.

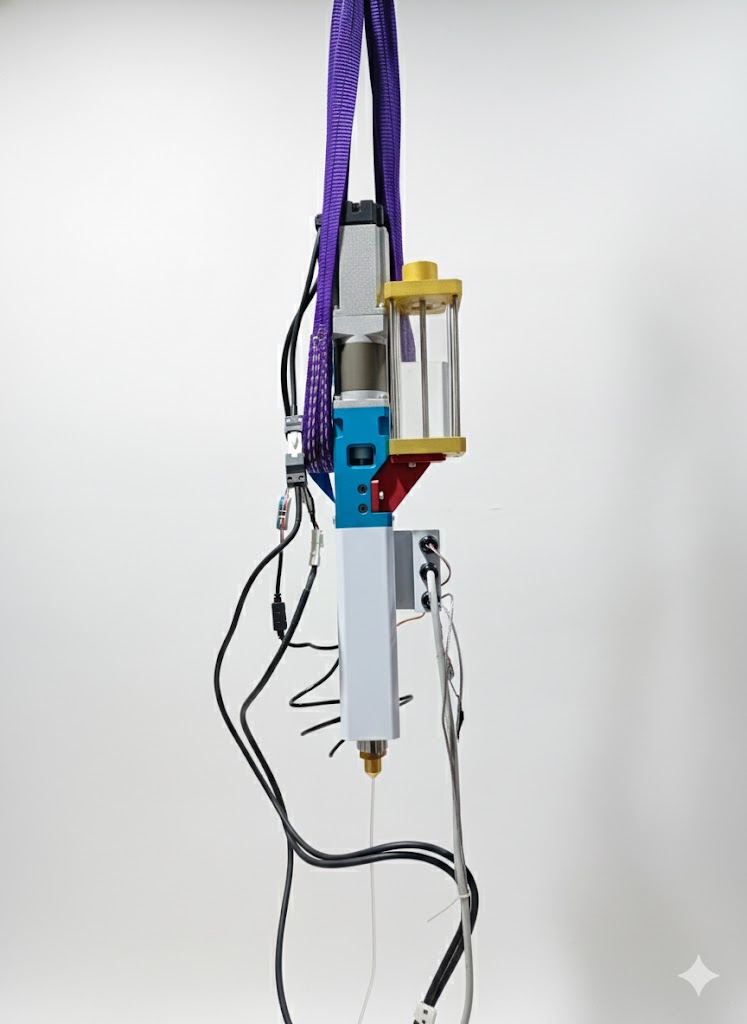

3. Integrated Pellet Extruder Kits for Robotics

RobotDigg’s extruder kits are designed for seamless integration into robotic cells. These are not just "parts," but complete thermal systems:

Multi-Zone Heating: Precise temperature control across the feed, compression, and metering zones to ensure the glass fibers are evenly distributed within the melt.

High-Torque Drive Systems: Fiber-filled pellets require more torque to shear and compress; RobotDigg kits utilize heavy-duty gearboxes to prevent motor stalling.

Modular Mounting: The kits are lightweight enough to be mounted on medium-payload robot arms while remaining rigid enough for high-speed paths.

4. Continuous Operation for Industrial Success

For users transitioning to 24/7 production, the combination of RobotDigg’s pellet extrusion technology and wear-resistant materials is the key to ROI. By upgrading to a nitrided or bimetallic system, operators can:

Reduce Downtime: Fewer replacements of screws and nozzles.

Maintain Precision: Consistent pressure ensures that the 100th layer looks as good as the 1st.

Expand Material Capability: Switch between CF-ABS, GF-PP, and even high-temp materials like GF-PEI with confidence.

Summary Whether you are building architectural pavilions or industrial tooling, the abrasive nature of LFAM materials demands professional-grade hardware. With RobotDigg’s Tungsten Nitride and Bimetallic upgrades, your pellet extruder is transformed into a robust, industrial powerhouse capable of tackling the most demanding composite materials on the market.

Recent post:

- Shredder Knife Material Comparative Analysis: 75Cr1, 9CrSi, and H13

- RobotDigg Components Power 1st Place IAAPA Award-Winning Game!

- Dexterity Hands Industry Report: The Democratization of Robotic Manipulation

- Professional Guide: Maximizing Performance of Miniature Linear Rails (Beyond the Myths)

- The Lab-Scale Breakthrough: RobotDigg’s Desktop Wire Coating Line for PEEK & Fluoropolymers