Why Tank-Style Chillers Aren't Always Best for Extrusion Lines

In the world of plastic extrusion, temperature control is everything. When setting up a cooling system, many operators instinctively reach for a Tank-Type Chiller because it’s an all-in-one solution.

However, if your extrusion line already includes a cooling trough or a built-in water tank, adding a tank-style chiller can create more problems than it solves. Here is why a Shell and Tube Chiller is often the superior choice for professional extrusion setups.

The "Double Tank" Conflict

Most extrusion lines (especially for tubing, filament, or profiles) feature an open cooling water tank where the hot plastic enters the water. If you connect a tank-style chiller to this system, you end up with two reservoirs. This leads to three major issues:

1. Pressure Imbalance: The pump inside the chiller and the pump on your extrusion line will rarely match perfectly. This often results in one pump "fighting" the other, leading to inconsistent flow rates.

2. Overflow Risks: Managing water levels in two separate tanks is a headache. If the return flow from the extrusion trough is slightly faster or slower than the chiller’s output, you risk flooding your workshop floor or running the chiller pump dry.

3. Thermal Efficiency: In a double-tank setup, you are essentially cooling water in one box to pump it into another box. This is less efficient than cooling the process water "in-line."

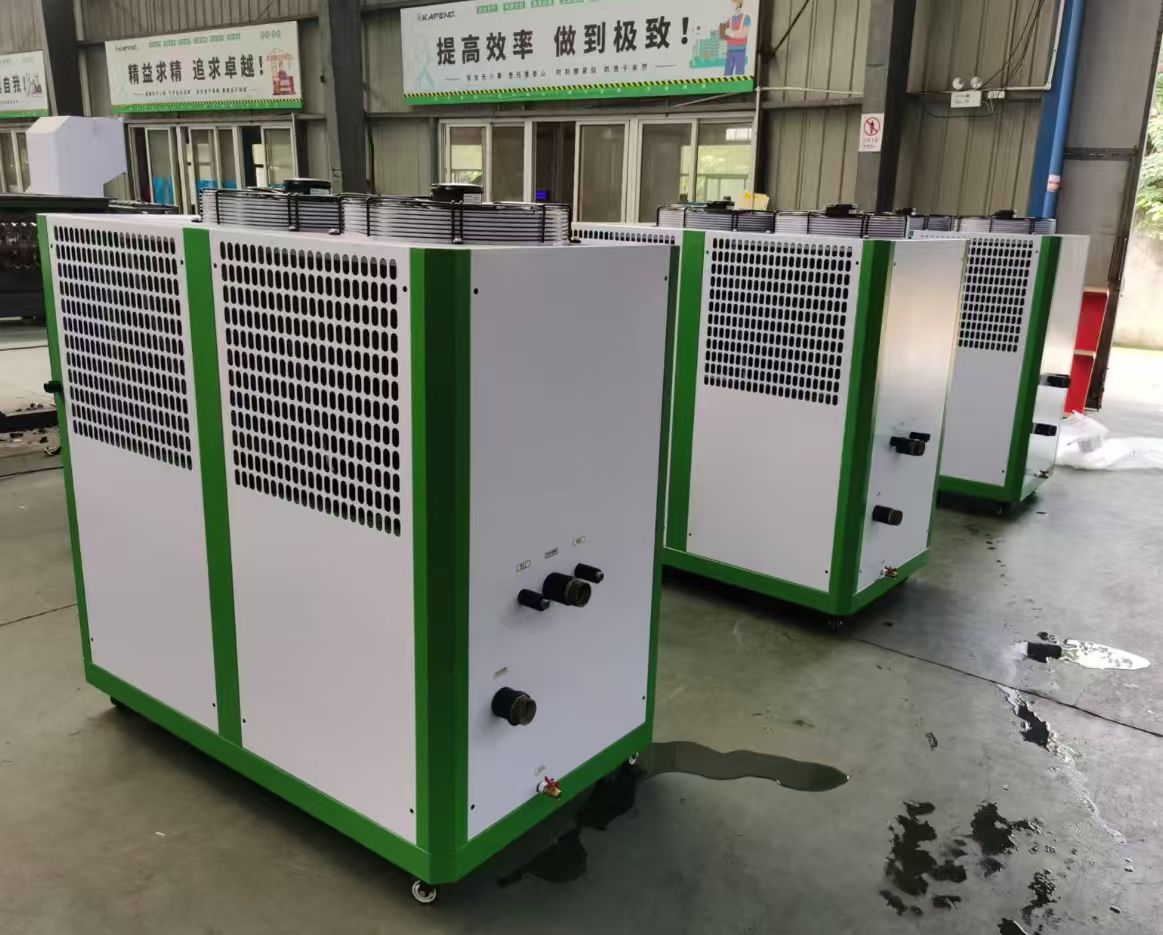

The Professional Alternative: Shell and Tube Chillers

For extrusion lines with existing water troughs, a Shell and Tube Chiller (or heat exchanger) acts as the perfect "bridge."

How it works: The chiller’s refrigerant flows through the tubes, while your extrusion line’s process water flows through the surrounding shell.

The Benefit: It cools the water while it is moving from the trough back to the spray heads. There is no secondary reservoir to manage, no overflow risk, and the system remains a single, streamlined loop.

RobotDigg Engineering Tip: Watch Your Water Quality

Extrusion cooling water often picks up "wax," plastic fines, or dust from the factory floor.

• Plate Heat Exchangers (PHE) are compact and efficient but clog easily in extrusion environments.

• Shell and Tube designs are the "workhorses"—their wider channels allow for small particles to pass through without causing a total system blockage, making them the most reliable choice for 24/7 production.

If you are building a new RobotDigg extrusion setup and your line already has a water tank, go with a Shell and Tube Chiller. It eliminates the headache of balancing water levels and provides a more stable thermal mass for consistent product dimensions.