The Future of Motion Control: Integrated Linear and Rotary Actuators

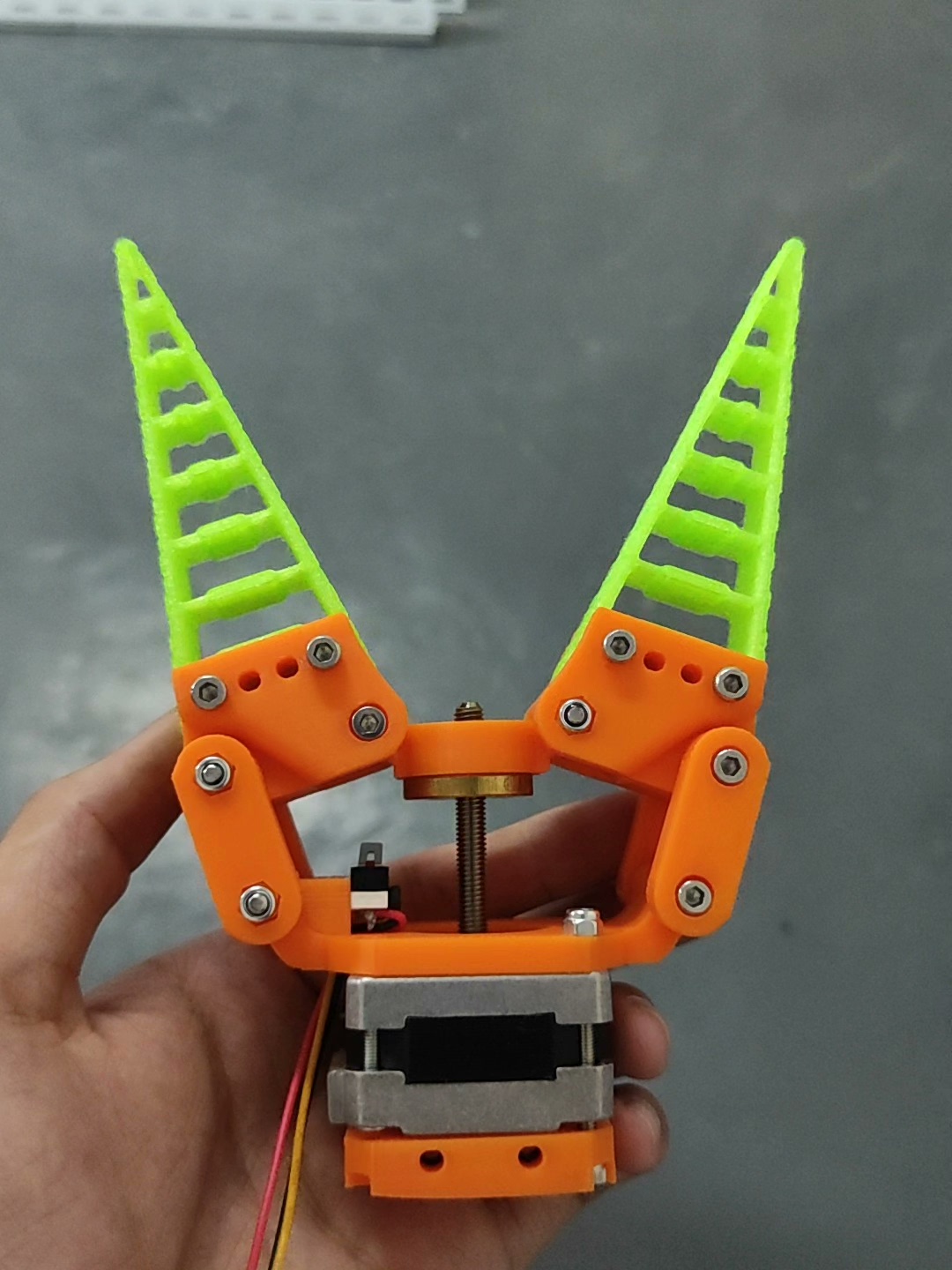

In the field of high-precision automation and robotics, the demand for compact, accurate, and efficient motion systems is higher than ever. Traditional setups, which relied on separate linear and rotary components connected mechanically, are giving way to advanced, integrated solutions. The ultimate goal is a single, zero-maintenance unit that can handle complex "pick-and-place" tasks with unparalleled speed and accuracy.

Integrated Linear Motor: The Coupler-Free, All-in-One Actuator

A linear motor with no coupling is a direct-drive system where the moving part (forcer) and the stationary part (stator) interact electromagnetically to produce linear motion. This design eliminates the need for mechanical couplings like ball screws, belts, or gears, which are sources of backlash, friction, and wear.

Key Features:

Direct Drive: The force is generated directly, leading to faster response times and higher acceleration.

Integrated Controller: The most advanced linear motors come with an integrated controller or drive electronics built directly into the motor housing. This reduces wiring, simplifies installation, and creates a more compact system. It allows for a "plug-and-play" solution, as the drive and motor are pre-tuned and matched.

High Precision: The absence of mechanical components results in zero backlash, enabling sub-micron level positioning accuracy and repeatability.

Linear motors are widely used in applications like semiconductor manufacturing, high-speed inspection, and precision dispensing, where speed and accuracy are paramount.

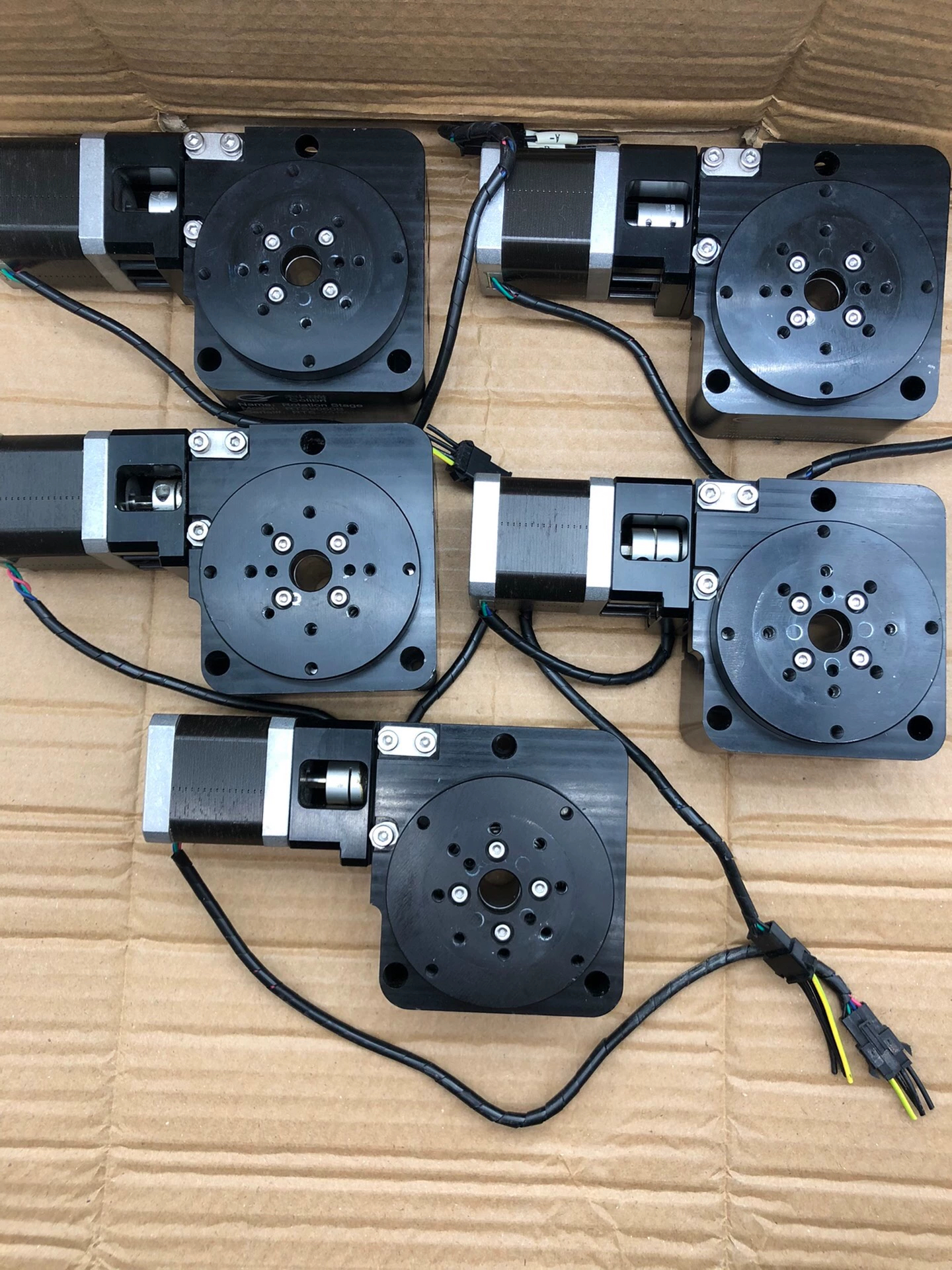

Integrated Rotary Table Motor: Precision Rotation with Zero Backlash

The ideal counterpart to a linear motor is a rotary table motor, also known as a torque motor. This type of motor is designed for high-precision angular positioning and continuous rotation.

Key Features:

Harmonic Drive Reducer: A harmonic drive reducer is a key component for achieving high-ratio speed reduction in a very small package. It's known for its high torque capacity, compact size, and, most importantly, zero backlash. This makes it the perfect choice for applications requiring extreme positional accuracy, such as robotic arms and high-precision indexing tables.

Hollow Shaft: Many rotary table motors feature a hollow shaft design. This is a crucial feature that allows for cables, wiring, air lines, or other components to be routed through the center of the motor. This streamlines the machine's design, reduces clutter, and enables more complex movements.

Integrated Encoder: An integrated encoder provides real-time feedback on the motor's angular position. High-resolution encoders are essential for closed-loop control, ensuring that the rotary table reaches and holds its target position with high accuracy.

Integrated Controller: Just like the linear motor, some advanced rotary table motors integrate the drive electronics and controller. This simplifies the system, reduces the number of components, and offers a more robust and compact solution.

The Concept of a Unified System

While a single product that perfectly combines all these features—a linear motor with an integrated controller and a rotary table motor with a harmonic drive, hollow shaft, and integrated controller—is not a common off-the-shelf item, the trend in the industry is to move towards this type of highly integrated, modular design.

Engineers and system integrators often combine these individual components to create multi-axis systems for specific applications, such as a "screw-driving machine" that performs high-speed linear motion (for rapid approach) and a precise rotary motion (for tightening). The future of motion control lies in these highly specialized, compact, and maintenance-free systems that can perform complex, multi-dimensional tasks with unprecedented precision and efficiency.

Recent post:

- The Realm of Motion: Unraveling the Mechanisms of Lead Screws, Ball Screws, Reversing Screw and Beyond

- Whirlwind Milling vs. CNC Milling for Screw Manufacturing and the Cost Implications for Different Screw Types

- The relationship between three common closed-loop modes and FOC control

- Transforming Waste into Value: The Powerhouse Machines of the Plastic Industry

- A Tale of Two Films: Calendering vs. Casting